Methods for Improving Concrete Quality on Site

Introduction

Concrete is often called the backbone of modern construction because it forms the foundation, columns, beams, and slabs of nearly every structure we build. A building’s strength and durability, whether it’s a huge skyscraper or a small residential home, are greatly influenced on the quality of the concrete utilized. Unfortunately, many construction failures around the world are traced back to poor-quality concrete—weak mixes, improper curing, or neglecting on-site practices. These mistakes not only weaken structures but also reduce their lifespan, leading to costly repairs or even catastrophic collapses.

Enhancing the quality of concrete on-site is a duty as well as a technical need. Engineers, contractors, and site supervisors must ensure that every stage—from material selection to curing—is handled with precision. The good news is that most problems can be avoided with proper planning, careful execution, and awareness of best practices.

In this guide, we will break down the most effective ways to improve the quality of concrete directly on-site. From choosing the right materials to proper placement and curing, each step is crucial in making sure your concrete stands the test of time.

Understanding the Importance of Concrete Quality

Concrete is more than just a mixture of cement, sand, gravel, and water—it’s the backbone of structural integrity. Its quality determines not only the strength of a structure but also its durability against weathering, load stress, and environmental conditions. Imagine pouring concrete that looks fine during construction but starts cracking after a year. Such failures often happen because quality checks were ignored during the early stages.

Poor-quality concrete leads to problems like reduced load-bearing capacity, corrosion of steel reinforcement, surface cracks, and water leakage. In severe cases, entire structures may collapse, putting lives at risk. That’s why engineers emphasize that concrete is not just about strength on paper but about how it performs over decades.

High-quality concrete, on the other hand, ensures safety, reduces maintenance costs, and enhances durability. For example, bridges, dams, and high-rise towers demand concrete that can resist not just heavy loads but also chemical attacks, temperature variations, and water seepage.

So, when we talk about improving concrete quality on-site, we are talking about safeguarding lives, investments, and the future of the structure itself. The process requires a holistic approach: selecting proper materials, mixing correctly, and maintaining strict supervision until the structure gains full strength.

Select High-Quality Raw Materials

The quality of concrete is only as good as the materials used in its preparation. If the raw materials are substandard, no amount of mixing or curing will save the concrete from failure. That’s why selecting the right materials is the first and most important step.

Cement:

- Always use fresh cement from reputable manufacturers.

- Check the manufacturing date and ensure that the cement has been stored in dry conditions.

- Expired or lumpy cement should never be used because it loses its binding properties.

Aggregates:

- Fine aggregates (sand) and coarse aggregates (gravel or crushed stone) make up nearly 70% of concrete volume.

- They must be clean, free from silt, clay, or organic matter.

- Well-graded aggregates improve strength and reduce voids in the mix.

Water:

- Many people underestimate water quality, but it directly affects concrete strength.

- The rule of thumb is simple: if water isn’t fit for drinking, it’s not fit for mixing concrete. Contaminated or salty water leads to chemical reactions that weaken the mix.

In addition to these, sometimes admixtures are used to enhance properties like workability, setting time, or durability.

To sum up, concrete quality begins before mixing—at the stage of selecting raw materials. A bad choice here creates irreversible damage later. It’s like cooking: if the ingredients are rotten, no matter how well you follow the recipe, the dish will fail.

Maintain Accurate Mix Proportions

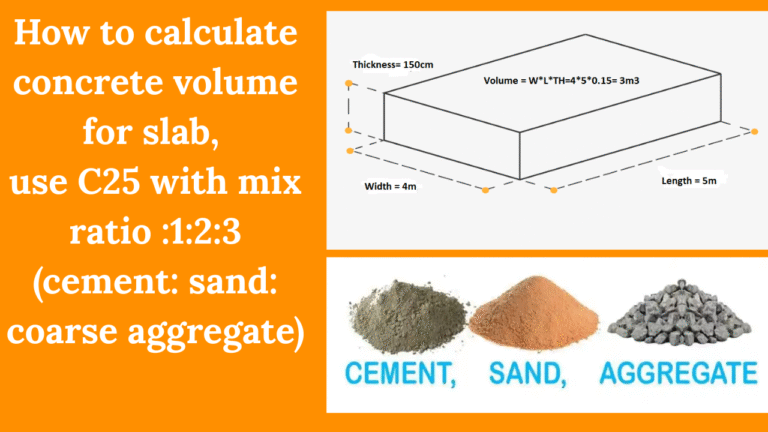

Once high-quality raw materials are selected, the next step is ensuring the right proportions. Concrete is a precise science—adding too much sand, not enough cement, or excess water can drastically change the strength. Engineers carefully design the mix ratio of concrete, which determines its strength.

For instance, a 1:2:4 ratio is commonly used in conventional construction (cement: sand: coarse material).But for high-strength concrete, different proportions are required. That’s why following standard guidelines such as IS codes (in India), ASTM standards (in the US), or Eurocodes (in Europe) is crucial.

There are two main ways to measure mix proportions:

- Volume batching – using containers to measure materials. This is common in small sites but less accurate.

- Weight batching – using weighing machines to measure materials precisely. This is preferred for large projects because it eliminates human error.

Inaccurate batching cause serious concerns, including:

- Too much cement raises expenses without enhancing strength;

- Too much sand weakens and creates shrinkage cracks; and

- Too much water weakens and porousizes the concrete.

Here, supervision on-site is crucial. Employees should receive training on how to adhere to the given proportions and steer clear of short cuts. As with adding too much sugar or too little salt to a recipe, inaccurate batching ruins the finished product.

Proper Mixing Techniques

Even if the right materials and proportions are used, poor mixing can still produce weak concrete. Proper mixing ensures that cement coats every particle of sand and aggregate evenly, creating a uniform and workable mix.

There are two main methods:

- Hand mixing: Used for small-scale works. The materials are spread on a platform, water is added gradually, and the mix is turned over until uniform. The problem is, it’s difficult to achieve consistency with hand mixing, and mistakes are common.

- Machine mixing: Done using concrete mixers. This method ensures uniformity, better quality, and saves time. Most large-scale projects mandate machine mixing for reliable results.

Some common mistakes during mixing include:

- Adding too much water at once

- Not mixing for enough time (standard is at least 2–3 minutes in a machine)

- Mixing materials in the wrong sequence

Uniform mixing results in concrete that has consistent workability, strength, and durability. Poorly mixed concrete, on the other hand, often leads to weak patches, honeycombing, and cracks after curing.

In short, mixing is like blending a smoothie—if you don’t blend well, you’ll end up with lumps. And in concrete, those lumps can cost you both strength and money.

Avoid Excess Water in the Mix

One of the most common mistakes on construction sites is adding too much water to concrete. Workers often do this to make the mix easier to handle, but what they don’t realize is that excess water is one of the biggest enemies of concrete strength.

The water-to-cement ratio (w/c ratio) has a significant impact on concrete’s strength. Ideally, this ratio should be kept as low as possible while still ensuring workability. When too much water is added, it dilutes the cement paste, leaving behind pores after evaporation. These pores weaken the structure, make it less durable, and allow water or harmful chemicals to seep in over time.

Excess water also leads to problems such as:

- Lower compressive strength

- Increased shrinkage and cracking

- Higher risk of segregation and bleeding

- Reduced resistance to weathering

Instead of adding more water, there are better alternatives to improve workability. For example, plasticizers and superplasticizers (types of admixtures) can be used to make the concrete flow easily without compromising strength. Another method is using well-graded aggregates, which naturally improve workability.

Think of it like cooking rice—adding too much water will leave you with a soggy mess. Concrete is no different; if you pour excess water, the final product will be weak and short-lived. Careful control of the water-cement ratio is therefore critical to maintaining concrete quality on site.

Avoid Bleeding and Segregation

- If not correctly managed, two significant problems that lower the quality of concrete are segregation and bleeding.

- When the coarse aggregates split off from the finer particles, an uneven distribution results from segregation. This frequently happens when the mixture is handled incorrectly, dumped from too high, or is excessively wet.

- Bleeding happens when too much water rises to the surface after the concrete is placed, and segregated concrete is weak and develops honeycombing (voids) after hardening. If more concrete is poured on top, this weakens the top layer, increases shrinkage cracks, and degrades the bond between layers.

- Use these procedures to avoid bleeding and segregation:

- • Preserve the proper ratio of cement to water (avoid mixtures that are too moist).

- Place concrete as close to its final position as possible, avoiding free-fall from more than 1.5 meters.

- Use admixtures like plasticizers to maintain workability without excess water.

- To release trapped air and disperse particles uniformly, make sure the compaction is correct.

Preventing segregation and bleeding is like making a smoothie—if the ingredients separate, the drink won’t taste right. Similarly, concrete needs proper handling to remain uniform and strong throughout its life.

Correct Placement of Concrete

Even the best mix can fail if it isn’t placed properly on site. Appropriate positioning is essential to prevent honeycombing, cold joints, and weak areas in the construction. Concrete must be placed quickly after mixing—delays can cause premature setting and reduce bonding.

Some best practices for proper placement include:

- Continuous pouring: Avoid long gaps between batches to prevent cold joints.

- Short dropping height: Never let concrete free-fall from a great height, as this leads to segregation. Instead, use chutes, buckets, or pumps.

- Layered placement: Place concrete in layers not exceeding 30–50 cm and compact each layer before adding the next.

- Avoid re-tempering: Never add water to partially set concrete to make it workable again. This drastically reduces strength.

In addition, proper supervision during placement ensures that the concrete fills every corner of the formwork and properly surrounds reinforcement bars. Poorly placed concrete creates voids that can reduce load capacity and expose steel to corrosion.

Think of placement like laying bricks in a wall—if you rush or leave gaps, the wall won’t be strong. Proper placement ensures that the structure gets maximum strength and durability from the mix you worked so hard to prepare.

Effective Compaction

Compaction is the process of removing air bubbles trapped in fresh concrete. If concrete isn’t compacted well, up to 10% of its volume could be air voids, drastically reducing its strength and durability.

There are two main methods of compaction:

- Manual compaction – using rods or tamping tools. This is suitable only for small works or when machinery isn’t available.

- Mechanical compaction – using vibrators (needle vibrators, surface vibrators, or formwork vibrators).

Proper compaction ensures:

- Increased density of concrete

- Better bonding between cement paste and aggregates

- Stronger reinforcement-concrete bond

- Higher durability and resistance to weathering

On the other hand, under-compaction leads to honeycombing, porous concrete, and poor strength, while over-compaction may cause segregation.

The goal is to strike the right balance. Workers should be trained to handle vibrators correctly, avoiding excessive vibration or leaving areas uncompacted. Compaction is like shaking a jar of marbles—if you don’t shake enough, there are gaps; if you shake too much, the small marbles settle separately. Controlled compaction ensures maximum strength and uniformity.

Curing for Strength and Durability

Curing is one of the most overlooked steps in concrete construction, yet it plays a decisive role in determining the strength and durability of the final structure. Curing refers to maintaining adequate moisture, temperature, and time conditions so that the cement can properly hydrate.

Without proper curing, concrete will not achieve its intended strength. For instance, concrete gains about 70% of its strength in the first 7 days, but only if it is kept moist. Neglecting curing can lead to surface cracks, reduced durability, and faster deterioration of the structure.

There are various ways to cure:

• Water curing: using moist burlap to drape, mist, or pond.

Applying curing agents to stop moisture loss is known as membrane curing.

• Precast companies use steam curing to hasten the development of strength. While mixed cement requires at least 14 days to cure, regular cement typically takes at least 7 days. Since moisture evaporates quickly in hot or windy conditions, curing becomes much more important.

Curing can be compared to taking care of a newborn. Just like babies need constant care in their early days, concrete needs proper curing to grow strong and durable. Skipping this step may save a little time, but it guarantees long-term problems.

Monitor Environmental Conditions

Concrete is highly sensitive to environmental factors such as temperature, humidity, and wind speed. Ignoring these conditions during mixing, placing, and curing can severely impact its strength and durability.

In hot weather concreting, the high temperature speeds up the setting process, which reduces workability and makes it difficult to place and finish the concrete properly. Rapid evaporation of water also increases the risk of plastic shrinkage cracks. To prevent this, contractors often use chilled water, shade nets, or retarders to slow down setting.

In cold weather concreting, the opposite problem occurs. If water in the concrete freezes before hydration is complete, it expands, causing microcracks that weaken the structure permanently. To combat this, site engineers use heaters, insulated blankets, or accelerators to maintain proper hydration.

Wind and humidity also play roles. Strong winds can cause rapid drying, leading to cracks, while high humidity may delay drying and finishing operations. Covering fresh concrete and monitoring conditions throughout the process helps ensure consistent quality.

In short, monitoring environmental conditions is like protecting a plant. Just as too much sun or frost can harm a seedling, extreme weather can destroy the quality of fresh concrete if not managed carefully.

Conduct On-Site Quality Tests

On-site testing is essential to confirm that the concrete being produced meets the required specifications. Without tests, it’s impossible to guarantee the quality and strength of the mix.

Some common on-site tests include:

- Slump Test – Measures the workability of fresh concrete. A standard cone mold is filled with concrete, lifted, and the slump (settlement) is measured. Too much slump indicates excess water, while too little slump means the mix is too stiff.

- Cube or Cylinder Test – Samples of fresh concrete are cast in molds and cured. After 7, 14, or 28 days, they are tested in a compression machine to check strength.

- Non-Destructive Testing (NDT) – Methods like rebound hammer and ultrasonic pulse velocity are used on hardened concrete to check strength without damaging the structure.

- Air Content Test – Ensures there isn’t excessive air in the mix, which can reduce strength.

These tests not only ensure compliance with standards but also help identify problems early. For example, if slump results show high water content, adjustments can be made immediately before placing the concrete.

Skipping quality tests is like driving a car without checking fuel or brakes—you may keep going for a while, but disaster is just around the corner. Regular on-site testing is the safety net that guarantees long-lasting and reliable concrete.

Train Site Workers and Supervisors

Even the best mix design and equipment won’t guarantee quality if the workforce is unskilled. Workers are the ones who actually handle mixing, placing, compaction, and curing on site, so their knowledge and training directly affect concrete quality.

Training site workers ensures they understand:

- The importance of following correct proportions.

- How to handle concrete without causing segregation.

- Proper use of vibrators for compaction.

- The need for curing and how to perform it.

Supervisors, on the other hand, must ensure strict monitoring of all processes. They are responsible for preventing shortcuts and making sure safety and quality standards are maintained.

Workshops, demonstrations, and refresher training sessions are excellent ways to keep workers updated. Many construction failures occur simply because workers add extra water for convenience or skip compaction to save time. These errors can be avoided with proper training.

A construction site can be compared to a football team. The team cannot win without talented and trained players, even if the engineer is the coach. In a same vein, skilled laborers are necessary to provide high-quality concrete on location.

Maintain Equipment in Good Condition

The quality of concrete also depends heavily on the condition of site equipment. Mixers, vibrators, pumps, and batching machines must be well-maintained to function properly. A faulty mixer may not blend materials evenly, while a damaged vibrator may fail to remove air voids, leaving weak spots in the structure.

To ensure equipment reliability:

- Perform regular inspections of all machines before use.

- Rather than waiting for malfunctions, adhere to a preventive maintenance schedule.

- Keep equipment clean, especially mixers, since hardened concrete residues affect mixing.

- Replace worn-out parts immediately to avoid delays and quality issues.

For example, a simple malfunction in a batching plant could alter the cement ratio in several cubic meters of concrete, creating an entire section of weak structure. Proper maintenance avoids such costly mistakes.

Using faulty equipment is like cooking with a broken oven—it doesn’t matter how good the recipe is, the outcome will always be poor. Consistent concrete quality is based on well-maintained equipment and tools.

Use Admixtures Wisely

Chemical additions known as additives change the characteristics of concrete. They can significantly increase durability, workability, and setting time when used properly. On the other hand, misuse or overuse may have adverse consequences.

Some common types of admixtures include:

- Plasticizers & Superplasticizers – Improve workability without extra water.

- Retarders – Slow down setting time, useful in hot weather.

- Accelerators: They increase speed and are helpful in cold climates.

- Air-Entraining Agents – Improve resistance to freeze-thaw cycles.

- Waterproofing Admixtures – Reduce permeability.

The key is to use them according to manufacturer’s recommendations and under engineer supervision. Overdosing can cause segregation, delayed setting, or even reduced strength.

Good practices should not be replaced by additives; rather, they should be viewed as supplementary. They can enhance quality but cannot compensate for poor materials or bad workmanship. It’s like adding spices to a dish—they can improve the flavor, but if the main ingredients are bad, the food still won’t taste right.

Regular Inspection and Documentation

Quality control doesn’t end with mixing and placing; it also requires continuous monitoring and proper documentation. Regular inspections ensure that every step of the process is executed correctly, while documentation provides accountability and a record for future reference.

Some essential practices include:

- Daily inspection checklists for mixing, placement, compaction, and curing.

- Recording test results from slump tests, cube tests, etc.

- Maintaining equipment logs for servicing and repairs.

- Documenting weather conditions that may affect concrete performance.

These records not only help track quality but also serve as evidence in case of disputes or future repairs. They also allow engineers to analyze past issues and improve construction practices over time.

In the absence of documentation and inspection, errors are overlooked and perpetuated. It’s like running a business without keeping financial records—you’ll never know if you’re making progress or heading toward loss. Consistent concrete quality and durable constructions are guaranteed by routine monitoring.

Conclusion

Concrete quality is the foundation of strong, safe, and durable structures. From selecting the right materials to proper curing, every stage plays a vital role. Poor-quality concrete doesn’t just weaken a building; it puts lives at risk and increases maintenance costs.

By following best practices—accurate mix proportions, proper mixing, avoiding excess water, careful placement, effective compaction, curing, and continuous monitoring—you can ensure that your concrete achieves maximum strength and longevity. Training workers, maintaining equipment, and using admixtures wisely further enhance quality. Finally, regular inspections and documentation tie all these practices together into a reliable quality-control system.

In short, achieving high-quality concrete is not about one big step, but about consistently getting the small details right. If every person on site commits to quality, the end result will be structures that stand strong for decades.