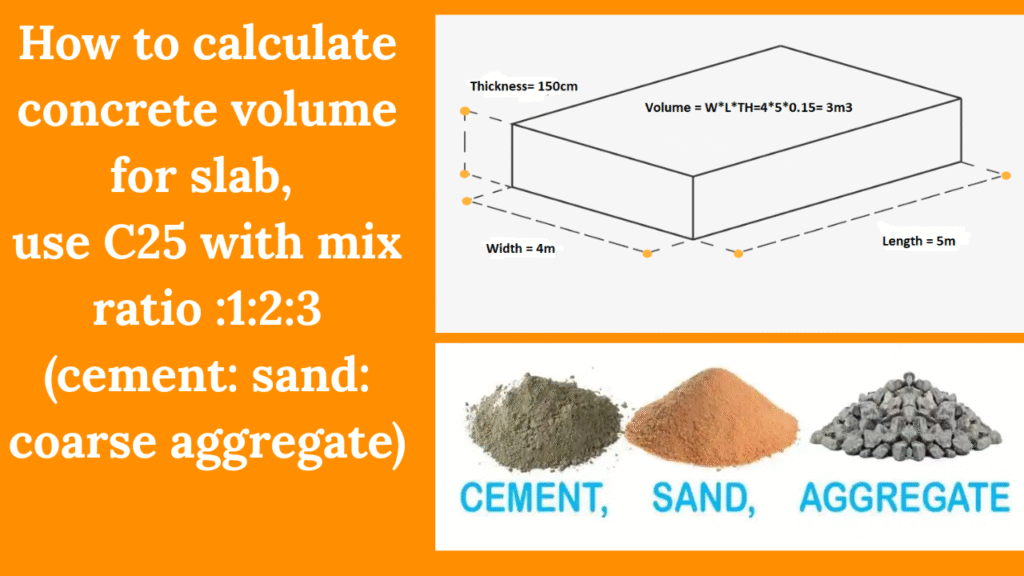

How to calculate concrete volume for slab, use C25 with mix ratio :1:2:3 (cement: sand: coarse aggregate)

Introduction

Concrete is one of the most widely used construction materials in the world, and for good reason—it’s strong, durable, and versatile. Whether you’re building a small house slab or a large commercial floor, knowing how to calculate the exact concrete volume is essential. If you underestimate, you’ll end up with shortages and delays; if you overestimate, you’ll waste money and materials. In this guide, we’ll walk through the step-by-step method to calculate the concrete volume required for a slab, using C25 grade concrete with a mix ratio of 1:2:3 (cement: sand: coarse aggregate). By the end, you’ll not only understand how to do the math but also how to apply it in real-life projects, ensuring accuracy and cost-effectiveness.

Understanding the 1:2:3 Mix Ratio

The ratio 1:2:3 means: 1 part cement, 2 parts sand (fine aggregate), 3 parts coarse aggregate, typically by volume. The total “parts” add to 6. That sum is the key to apportioning the dry materials before adding water. If you scale the parts up or down—1 bucket cement, 2 buckets sand, 3 buckets stone—you preserve the proportion, which keeps the fresh concrete workable and the hardened concrete in the expected strength ballpark (again, water control matters).

Why is 1:2:3 so popular? It strikes a balance: enough cement paste to coat and bind aggregates, enough sand to fill voids and improve finish ability, and enough coarse aggregate to reduce paste demand and shrinkage. For slabs, it typically produces a comfortable slump range for hand placing and power-troweling without feeling soupy (as long as the w/c ratio stays sane). It also accommodates common 20 mm nominal maximum size aggregate—easy to procure almost anywhere.

A common misunderstanding is treating 1:2:3 as a weight ratio. Cement is dense (about 1440 kg/m³ bulk), sand is variable (≈1500–1700 kg/m³ bulk), and coarse aggregate is often ≈1350–1550 kg/m³ bulk (depending on size and shape). If you used 1:2:3 by weight, you’d overload the mix with aggregate relative to paste, wrecking workability and potentially underperforming in strength. Always clarify: unless explicitly stated otherwise, conventional site ratios like 1:2:3 are by volume.

Why the Ratio Sums Matter

Because 1 + 2 + 3 = 6, each “part” is 1/6 of the total dry volume before water. In practical calculations, we first inflate the wet concrete volume (1 m³ of finished concrete) to a dry ingredient volume using a factor (commonly 1.54). Then we split that dry volume across the 6 parts. This gives us individual volumes for cement, sand, and stone—which we convert to mass (bags) or m³ as needed. That simple arithmetic is the backbone of every concrete quantity takeoff you’ll do for nominal mixes.

Step 1: Calculate Wet Concrete Volume

First, determine the slab’s size.

Suppose slab dimensions:

- Length = 5 m

- Width = 4 m

- Thickness = 0.15 m (150 mm)

Wet Volume=L×W×T =5×4×0.15=3.0 m3= 3

So, wet concrete required = 3.0 m³.

Step 2: Convert to Dry Volume

Concrete ingredients (cement, sand, aggregate) require more volume than wet concrete due to voids and wastage.

We usually add 54% extra:

Dry Volume=Wet Volume×1.54=Wet Volume×1.54 =3.0×1.54=4.62m3

So, dry volume = 4.62 m³.

Step 3: Calculate Mix Proportions

Mix ratio = 1: 2: 3 → total parts = 1 + 2 + 3 = 6 parts

- Cement = (1/6) ×4.62=0.77 m3 =0.77m3

- Sand = (2/6) ×4.62=1.54m3

- Coarse Aggregate = (3/6) ×4.62=2.31m3

Step 4: Convert Cement Volume to Bags

Density of cement = 1440 kg/m³

50 kg x 1 bag of cement equals 0.035 m³.

- Cement (kg)=0.77×1440=1109 kg

- No. of bags= (1109/50) ≈22.2 bags

So, 22–23 bags of cement required.

Step 5: Water Calculation (Water-Cement Ratio for C25)

For C25 concrete, water-cement ratio ≈ 0.5.

Water=1109×0.5=555 kg≈555 liters

Final Requirement for 5m × 4m × 0.15m Slab (C25, 1:2:3 mix)

- Cement: ~22–23 bags (1109 kg)

- Sand: ~1.54 m³

- Coarse Aggregate: ~2.31 m³

- Water: ~555 liters

Conclusion

Calculating concrete volume for a slab doesn’t have to be complicated. Once you know the slab dimensions, adjusting for dry volume, and applying the correct mix ratio, the process becomes straightforward. For a C25 mix of 1:2:3, the breakdown of cement, sand, aggregate, and water is easy to derive with simple formulas. Using this method ensures you avoid costly mistakes, maintain quality, and achieve the desired strength for your slab. Remember, precision in calculations leads to efficiency in construction. So, whether you’re a contractor, an engineer, or a DIY builder, mastering this calculation is a skill that pays off every time you lay a slab.Top of Form