Concrete Mix Design: A Complete Guide for Beginners and Professionals

Introduction to Concrete Mix Design

Finding the ideal ratios of cement, water, fine and coarse aggregate, and occasionally admixtures to provide the strength and durability required for a given construction project is the art and science of designing a concrete mix. Imagine concrete as a cake—if you don’t balance the ingredients properly, it either crumbles apart or turns too hard to chew. Similarly, the wrong concrete proportions can lead to structural failure, cracks, or reduced lifespan of a building.

The significance of mix design resides in its capacity to produce concrete that is both strong and workable. It helps engineers avoid wasting cement or using excessive water, which often weakens the structure. For instance, if too much water is added, the concrete becomes easy to work with but weakens after hardening. On the other hand, too little water makes the mix stiff, hard to place, and prone to honeycombing.

Concrete mix design has evolved significantly over time. In the early days, builders used rough proportions like “1:2:4” (cement: sand: aggregate) without scientific testing. Although minor tasks might be completed with this nominal mix, modern engineering requires accuracy. Today, codes like IS 10262 (India), ACI 211 (USA), and BS 8500 (UK) guide engineers in producing mixes suitable for different structures—whether it’s a residential building, a highway, or a high-rise skyscraper.

In short, concrete mix design is not just about mixing cement and aggregates—it’s about ensuring safety, durability, and economy while tailoring concrete to meet specific structural needs.

Fundamentals of Concrete Mix Design

To understand concrete mix design, you must first understand the ingredients that go into making it. Each component has a unique role that directly affects the quality and strength of the final product.

. Cement

Cement is the binding material in concrete. When mixed with water, it undergoes hydration—a chemical reaction that hardens and holds the aggregates together. Different grades of cement (such as OPC 33, 43, and 53 in India) are used depending on structural requirements.

- Aggregates (Fine and Coarse):

Approximately 60–75% of the volume of concrete is composed of aggregates. Fine aggregates (sand) fill the voids between coarse aggregates (gravel or crushed stone), improving workability and reducing cement demand. The size, shape, and grading of aggregates greatly influence concrete’s strength and durability.

- Water:

Water activates cement hydration and provides workability. However, the amount of water is critical. Excess water increases porosity, reducing strength, while insufficient water makes the mix difficult to place and compact.

- Admixtures:

Modern concrete often uses chemical admixtures like plasticizers, accelerators, retarders, and air-entraining agents to modify properties such as setting time, strength, and workability.

When designing a mix, the water-to-cement ratio (w/c ratio) is the most crucial element. Lower ratios generally yield higher strength, provided the concrete can still be placed and compacted properly. For instance, structural concrete typically has a w/c ratio of 0.4 to 0.5.

To summarize, concrete is not just a random mixture—it’s a carefully engineered combination where each ingredient plays a vital role. A well-designed mix ensures strength, durability, workability, and economy, making it the backbone of modern construction.

Methods of Concrete Mix Design

Over the years, several methods have been developed worldwide to design concrete mixes scientifically. The choice of method often depends on local practices, available materials, and code requirements.

- Nominal Mix vs. Design Mix:

- Nominal Mix uses fixed proportions like 1:2:4 or 1:1.5:3 (cement: sand: aggregate). It is simple but not precise, as it doesn’t consider variations in material quality.

- Design Mix is based on laboratory tests and calculations, ensuring concrete meets required strength and durability with economy. Modern projects prefer design mix.

- India’s IS Code Method (IS 10262: 2019):

This method involves calculating target mean strength, selecting w/c ratio, and adjusting proportions based on trials. In India, it is frequently utilized for both commercial and residential projects.

- ACI Method (American Concrete Institute):

The ACI 211 method emphasizes statistical data and past performance. It provides step-by-step guidelines for selecting mix proportions based on workability, strength, and exposure conditions.

- DOE Method (UK – Department of Environment):

This method is more empirical, focusing on achieving desired workability and strength using charts and tables. In the UK and other Commonwealth nations, it has widespread popularity.

Each method has its strengths, but they all share one goal: producing concrete that is strong, durable, and economical. Engineers may even combine insights from different methods depending on project requirements.

Step-by-Step Procedure of Concrete Mix Design

Concrete mix design is a systematic process. Here’s a breakdown:

- Step 1: Target Mean Strength

Since not all batches of concrete will achieve the exact same strength, engineers design for a higher “target mean strength” than the characteristic strength required. This ensures safety and reliability.

- Step 2: Selection of Water-Cement Ratio

Based on strength requirements and exposure conditions, a suitable w/c ratio is chosen. Lower ratios increase strength but reduce workability, so balance is essential.

- Step 3: Calculation of Water Content

The amount of water depends on desired workability, aggregate size, and use of admixtures. For instance, more water is needed for concrete with a higher workability, which is utilized in extensively reinforced structures.

- Step 4: Cement Content Determination

After determining the water content and w/c ratio, the cement content is calculated. Codes also specify minimum cement content for durability under different exposure conditions.

- Step 5: Aggregate Proportioning

Aggregates are divided into fine and coarse fractions. The right blend ensures workability and reduces voids. Poorly graded aggregates can lead to segregation and honeycombing.

- Step 6: Trial Mixes and Adjustments

Lastly, to assess durability, workability, and strength, trial mixtures are made in the lab. Adjustments are made until the desired mix is achieved.

This step-by-step approach ensures precision and reliability, unlike guesswork used in nominal mixes.

Factors Affecting Concrete Mix Design

Concrete mix design is influenced by several external and internal factors:

. Workability Requirements:

The term “workability” describes how simple it is to pour, compact, and finish concrete. For example, mass concreting (like dams) requires low workability, while heavily reinforced structures need high workability.

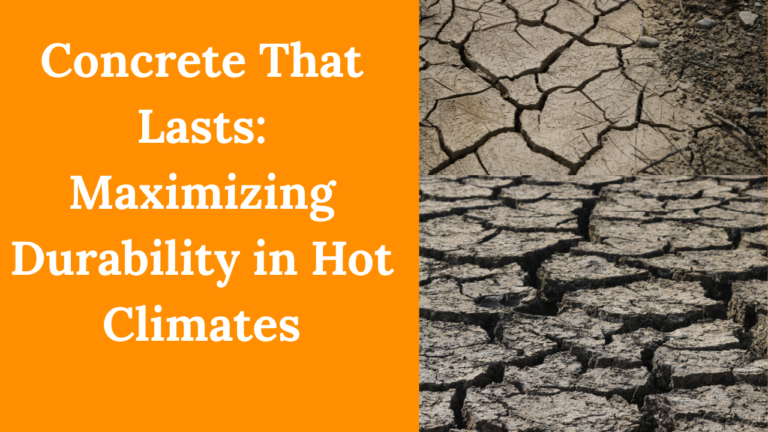

- Exposure Conditions:

Concrete exposed to harsh environments—like marine structures or industrial plants—needs higher durability. This means adjusting mix proportions, lowering w/c ratio, and sometimes using special admixtures.

- Durability Factors:

Durability depends on resistance to weathering, chemical attack, and abrasion. Using proper cement type, air entrainment, and low permeability helps increase lifespan.

- Economical Considerations:

While cement improves strength, it is also the most expensive ingredient. A good mix design minimizes cement use without compromising quality by optimizing aggregates and admixtures.

In short, mix design is not just science—it’s also about balancing strength, workability, durability, and cost for each unique project.

Methods of Quality Control in Concrete Mix Design

Concrete mix design does not end once proportions are decided in the laboratory. On-site quality control is just as important to ensure the designed mix performs as expected. Without strict control, the strength and durability of concrete may vary widely, leading to costly repairs or structural risks.

Material Testing and Approval:

Before any mix design is implemented on-site, materials such as cement, aggregates, and water must be tested for quality. Cement is checked for fineness, setting time, and strength; aggregates are tested for gradation, shape, and specific gravity; while water is tested for impurities that may affect hydration. Only approved materials should be used.

. Batching Accuracy:

Accurate measurement of materials is crucial. For greater accuracy, weight batching is recommended over manual volume batching, which frequently results in irregularities. Automatic batching plants further enhance consistency by eliminating human errors.

- Mixing and Homogeneity:

Concrete must be mixed thoroughly to ensure even distribution of cement paste around aggregates. Insufficient mixing can cause weak zones, segregation, or honeycombing. On-site drum mixers, pan mixers, or batching plants must be used depending on project scale.

- Slump Test for Workability:

To determine workability, a slump test is performed prior to concrete placement. A low slump indicates stiff concrete, while a high slump may mean excess water. Maintaining the right slump is key for placing and compacting concrete properly.

- Cube Test for Compressive Strength:

To confirm strength, concrete cubes or cylinders are cast and tested after seven and twenty-eight days. If results fall below target mean strength, adjustments are made in the mix or materials.

- On-Site Adjustments:

Weather, temperature, and handling conditions affect concrete. For example, hot weather accelerates setting, so retarding admixtures may be added. Continuous monitoring ensures the mix adapts to real-time conditions.

Quality control ensures that the designed mix does not remain just a laboratory achievement but translates into strong, durable, and economical concrete on-site.

Workability of Concrete in Mix Design

One of the most important considerations when designing a concrete mix is workability. It describes the ease with which new concrete may be mixed, moved, laid, and compacted without bleeding or separating. Simply put, workable concrete flows smoothly into place and fills all voids around reinforcement without extra effort.

- Factors Affecting Workability:

- Water Content: More water increases workability but lowers strength.

- Aggregate Properties: Rounded aggregates improve workability compared to angular aggregates.

- Admixtures: Superplasticizers enhance workability without increasing water content.

- Temperature and Climate: Hot weather reduces workability as water evaporates quickly.

- Methods to Measure Workability:

- Slump Test: Measures consistency and flowability.

- The Compaction Factor Test measures the ease of compacting concrete.

- Flow Table Test: Common for high-workability concrete mixes.

- Workability Requirements in Different Applications:

- Low workability (slump 25–75 mm) is used in mass concreting such as dams.

- Medium workability (slump 50–100 mm) is used in reinforced concrete structures like beams and slabs.

- High workability (slump 100–175 mm) is necessary for pumped concrete and crowded reinforcing.

In mix design, it can be difficult to strike a balance between strength and workability. Excessive workability may cause segregation, while poor workability results in honeycombing. Hence, proper proportioning and admixture use are crucial.

Durability Considerations in Concrete Mix Design

Durability refers to the ability of concrete to resist environmental conditions over its service life without losing strength or requiring major repairs. A durable structure saves money, reduces maintenance, and ensures safety.

- Factors Influencing Durability:

- Steel reinforcement corrodes as a result of highly permeable concrete’s ability to let chemicals, salts, and water in.

- Water-Cement Ratio: Lower ratios improve durability by reducing voids.

- Type of Cement: Sulphate-resistant cement or blended cement (PPC, PSC) is used in aggressive environments.

- Admixtures: Air-entraining agents enhance freeze-thaw resistance.

- Conditions and Requirements for Exposure (per IS 456):

- Mild Exposure: Interiors, where concrete is not subjected to moisture or chemicals.

- Concrete subjected to moisture but not to a serious chemical attack is said to have moderate exposure.

- Severe Exposure: Coastal regions with salt-laden air or industrial areas.

- Chemical plants, freezing conditions, and marine constructions are examples of Very Severe/Extreme Exposure.

- Durability Measures in Design:

- Use low w/c ratio (<0.45 for severe exposure).

- Ensure minimum cement content as specified by codes.

- Provide proper cover to reinforcement to protect from corrosion.

- Use supplementary cementitious materials (fly ash, silica fume, slag) to enhance durability.

Durability is just as important as strength. A structure with high compressive strength may still fail early if it is not designed for durability in its environment.

Economical Aspects of Concrete Mix Design

Cost is a major factor in any construction project. Since cement is the most expensive component of concrete, mix design aims to achieve required strength and durability with the minimum cement content possible.

- Reducing Cement Usage Without Sacrificing Strength:

- Optimize aggregate proportions to reduce voids.

- Use admixtures to reduce water demand.

- Use supplementary cementitious materials like fly ash, slag, or silica fume to partially replace cement.

- Balancing Economy and Performance:

- High-strength concrete requires more cement and costly admixtures, but it reduces structural member sizes, saving reinforcement and formwork costs.

- For mass projects like pavements, economy takes priority, so lower cement content mixes are preferred.

- Waste Reduction and Sustainability:

Eco-friendly mix design involves using recycled aggregates, industrial by-products, and minimizing cement use to reduce carbon footprint. Sustainable construction is becoming a major priority worldwide.

In conclusion, concrete mix design is not just about strength—it’s about achieving strength, durability, and economy in the most efficient way possible.

Role of Admixtures in Concrete Mix Design

Admixtures are special ingredients added to concrete, other than cement, water, and aggregates, to modify its properties. They are often described as the “spices” in a recipe—used in small quantities but capable of dramatically improving performance. Without admixtures, modern concrete structures like high-rise buildings, bridges, or tunnels would be difficult to construct economically and efficiently.

- Types of Admixtures:

- Plasticizers and Superplasticizers: Improve workability without increasing water content. This allows for a lower water-cement ratio, which improves strength.

- Accelerators: Speed up the setting and hardening process, useful in cold weather or when rapid strength gain is required.

- Retarders: Delay setting time, helpful in hot weather or when concrete has to be transported over long distances.

- Air-Entraining Agents: Introduce tiny air bubbles in the mix, enhancing freeze-thaw resistance.

- Mineral Admixtures (Fly Ash, Silica Fume, Slag): Improve durability, reduce heat of hydration, and make concrete more sustainable.

- Benefits of Using Admixtures:

- Better workability and ease of placement.

- Reduced water demand and cement consumption.

- Improved durability against harsh environmental conditions.

- Enhanced finishing and reduced shrinkage cracks.

Concrete with additives is more intelligent, resilient, and cost-effective. They enable engineers to modify the characteristics of concrete to satisfy extremely particular building requirements.

Mix Design for Different Grades of Concrete

Concrete is classified into grades based on its characteristic compressive strength (measured in MPa at 28 days). Mix design varies depending on the grade required.

- Low-Strength Concrete (M10, M15):

- Lean concrete, flooring, and pathways are common non-structural applications for it.

- Nominal mixes (1:3:6 or 1:2:4) are usually sufficient.

- Economy is prioritized over high strength.

- Medium-Strength Concrete (M20, M25, M30):

- Commonly used in residential buildings, beams, slabs, and columns.

- Requires design mix for consistency and durability.

- Balance between strength, workability, and cost.

- High-Strength Concrete (M40 and above):

- Used in high-rise buildings, bridges, and special structures.

- demands a low water-to-cement ratio, exact design mixing, and premium aggregates.

- Admixtures like superplasticizers and silica fume are essential.

This process ensures that every grade meets strength and durability requirements for its intended purpose.

Case Study: Concrete Mix Design for High-Rise Buildings

High-rise structures demand superior concrete performance. With tall buildings, loads are greater, reinforcement is congested, and durability must be ensured over decades. Let’s explore a real-world scenario.

- Challenges Faced in High-Rise Mix Design:

- Need for high strength (often M50 or higher).

- High workability required due to dense reinforcement.

- Pumpable concrete for vertical transportation.

- Durability against carbonation, chloride attack, and environmental exposure.

- Mix Design Approach:

- Use of high-quality crushed aggregates for better bond.

- Low water-cement ratio (0.35 or below).

- Superplasticizers to maintain workability at low water content.

- Partial replacement of cement with silica fume or fly ash to enhance durability.

- Outcome:

Such carefully designed mixes ensure the structure can withstand heavy loads, resist deterioration, and minimize maintenance costs over its lifespan. Without a scientific mix design, constructing skyscrapers like Burj Khalifa or Shanghai Tower would be impossible.

Sustainability in Concrete Mix Design

There is growing pressure on the construction sector to implement sustainable practices. Cement production alone contributes nearly 7% of global CO₂ emissions, making eco-friendly mix design a necessity.

- Use of Supplementary Cementitious Materials (SCMs):

- Fly Ash: A by-product of thermal power plants, improves durability and reduces cement usage.

- Ground Granulated Blast Furnace Slag (GGBS): Enhances resistance to chemical attack.

- Silica Fume: Improves strength and impermeability.

- Recycled Aggregates:

Concrete debris from demolished buildings can be crushed and reused as aggregates, reducing waste and saving natural resources.

- Optimizing Mix for Carbon Reduction:

- Reducing cement content wherever possible.

- Using blended cements instead of ordinary Portland cement.

- Incorporating carbon capture technologies during cement manufacturing.

- Green Concrete Movement:

Globally, engineers are experimenting with geopolymer concrete, which uses industrial by-products instead of cement, and self-healing concrete, which repairs its own cracks using bacteria.

Sustainable mix design not only saves money but also reduces the environmental footprint of construction, making it the future of concrete technology.

Typical Concrete Mix Design Errors and How to Prevent Them

Even with advanced guidelines, mistakes in mix design and execution are common, leading to poor performance.

- Overlooking Material Variability:

Aggregates from different sources may have different moisture content and grading. Mix performance becomes inconsistent when this is not taken into consideration. - Excessive Water Addition on Site:

For convenience of placing, workers frequently add more water, unwittingly weakening the concrete. Strict supervision is necessary to prevent this. - Ignoring Trial Mixes:

Skipping laboratory trials results in poor control over strength and workability. Always test before finalizing. - Neglecting Exposure Conditions:

Using the same mix for all environments is risky. Concrete exposed to marine environments needs special durability measures. - Inadequate Curing:

Even a well-designed mix fails if not cured properly. Curing preserves moisture for hydration, guaranteeing durability and strength.

How to Avoid:

- Conduct regular material tests.

- Train site workers about proper water addition.

- Perform multiple trial mixes before approval.

- Follow exposure-based requirements in IS 456 or ACI codes.

- Ensure at least 7–14 days of curing.

By avoiding these mistakes, engineers ensure that the designed mix performs well throughout the structure’s life.

Comparison of Different Mix Design Methods

Concrete mix design methods vary around the world, each developed to suit local materials and construction practices. While their approaches differ, their ultimate goal remains the same: producing durable and economical concrete Let’s examine some of the most popular approaches.

- IS Code Method (India – IS 10262:2019):

- Based on target mean strength and statistical data.

- Provides step-by-step guidelines for mix proportioning.

- Widely used in India for both small and large projects.

- Emphasizes durability and exposure conditions as per IS 456.

- ACI Method (American Concrete Institute – ACI 211):

- Uses statistical analysis and trial batches.

- More flexible in adjusting proportions based on workability and strength.

- Popular in the U.S. and many international projects.

- DOE Method (UK – Department of Environment):

- Based on empirical data and charts.

- Emphasizes workability and practical considerations.

- Preferred in the UK and many Commonwealth nations.

- Comparison Table:

| Criteria | IS Code Method | ACI Method | DOE Method |

| Primary Focus | Durability + Strength | Strength + Workability | Practical Workability |

| Ease of Use | Moderate | More Complex | Relatively Simple |

| Reliability | High (Code-based) | Very High (Statistical) | Moderate (Empirical) |

| Application | India, Asia | USA, Global Projects | UK, Commonwealth |

The location of the project, the coding specifications, and the materials’ availability all influence the best approach. Engineers may even adapt a hybrid approach, borrowing the best practices from multiple methods.

Practical Example of Concrete Mix Design (M30 Grade)

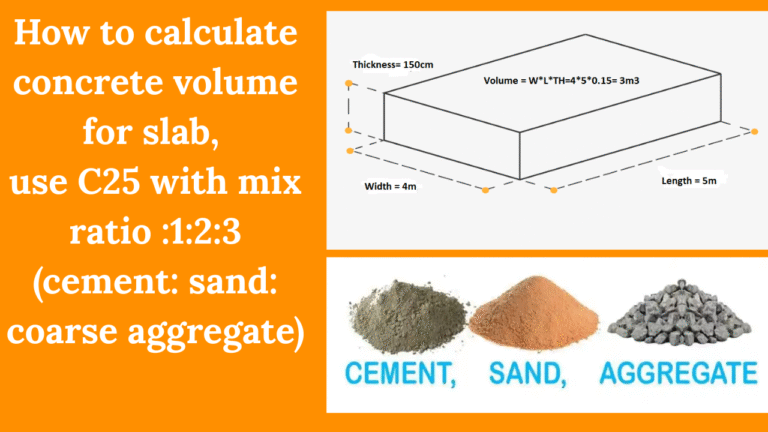

To make mix design more practical, let’s walk through a simplified example for M30 grade concrete using the IS method.

- Step 1: Mean Strength Target

30 MPa is the characteristic strength.

The assumed standard deviation is 5 MPa.

Strength of the Target Mean = 30 + (1.65 × 5) = 38.25 MPa - Step 2: Water-Cement Ratio:

According to IS 456 guidelines, the w/c ratio should be 0.45 for the necessary durability.

- Step 3: Water Content

Water content = 186 kg/m³ for 20 mm aggregate and moderate workability. - Step 4: Cement Content

Cement = Water ÷ w/c = 186 ÷ 0.45 = 413 kg/m³

(Checked against minimum requirement: safe). - Step 5: Aggregate Proportioning

Fine Aggregate = 35% (approx.)

Coarse Aggregate = 65% (approx.) - Step 6: Trial Mix

Prepare trial batches in the lab, check workability and cube strength at 7 and 28 days, and adjust if necessary. - Final Mix Proportions (Approx.):

Cement, sand, aggregate, and water equal 1 1.6 2.8 0.45

This example shows how step-by-step calculations ensure concrete meets both strength and durability requirements.

Future Trends in Concrete Mix Design

Concrete technology is rapidly evolving. Future mix designs will not just focus on strength and durability but also sustainability, innovation, and adaptability.

- Self-Healing Concrete:

Researchers are developing concrete with embedded bacteria that produce limestone to seal cracks automatically. This reduces maintenance costs and extends lifespan. - Geopolymer Concrete:

Instead of cement, this mix uses industrial by-products like fly ash and slag, activated by alkaline solutions. It drastically reduces carbon emissions. - Ultra-High-Performance Concrete (UHPC):

UHPC achieves strengths above 150 MPa, with superior durability and flexibility. It is being used in bridges and defense structures. - 3D Printable Concrete:

Additive manufacturing is revolutionizing construction. 3D concrete printing requires special mix designs with high flowability but quick setting times. - Smart Concrete:

Incorporating sensors into concrete allows real-time monitoring of strength, temperature, and stress. This makes structures safer and maintenance more efficient.

The future of concrete mix design is moving towards greener, stronger, and smarter solutions, making it more adaptable to modern construction challenges.

Conclusion

Concrete mix design is more than just a technical calculation—it is the foundation of every safe, durable, and economical structure. From ancient Roman mixtures to today’s high-tech UHPC and sustainable green concretes, mix design has continuously evolved.

Four important characteristics are balanced in a well-designed mix: affordability, workability, durability, and strength. Whether constructing a small house, a massive dam, or a futuristic skyscraper, the right mix ensures longevity and performance.

As technology develops, sustainability, creativity, and adaptation will be key components of concrete’s future. Engineers will increasingly use smart concrete, eco-friendly binders, and AI-driven optimization to make concrete more efficient and sustainable than ever before.